Dense fiberglass grating covers

Phone number:

Email:

Address:

Bedriftvegen 34

4353 Klepp Station

Norway

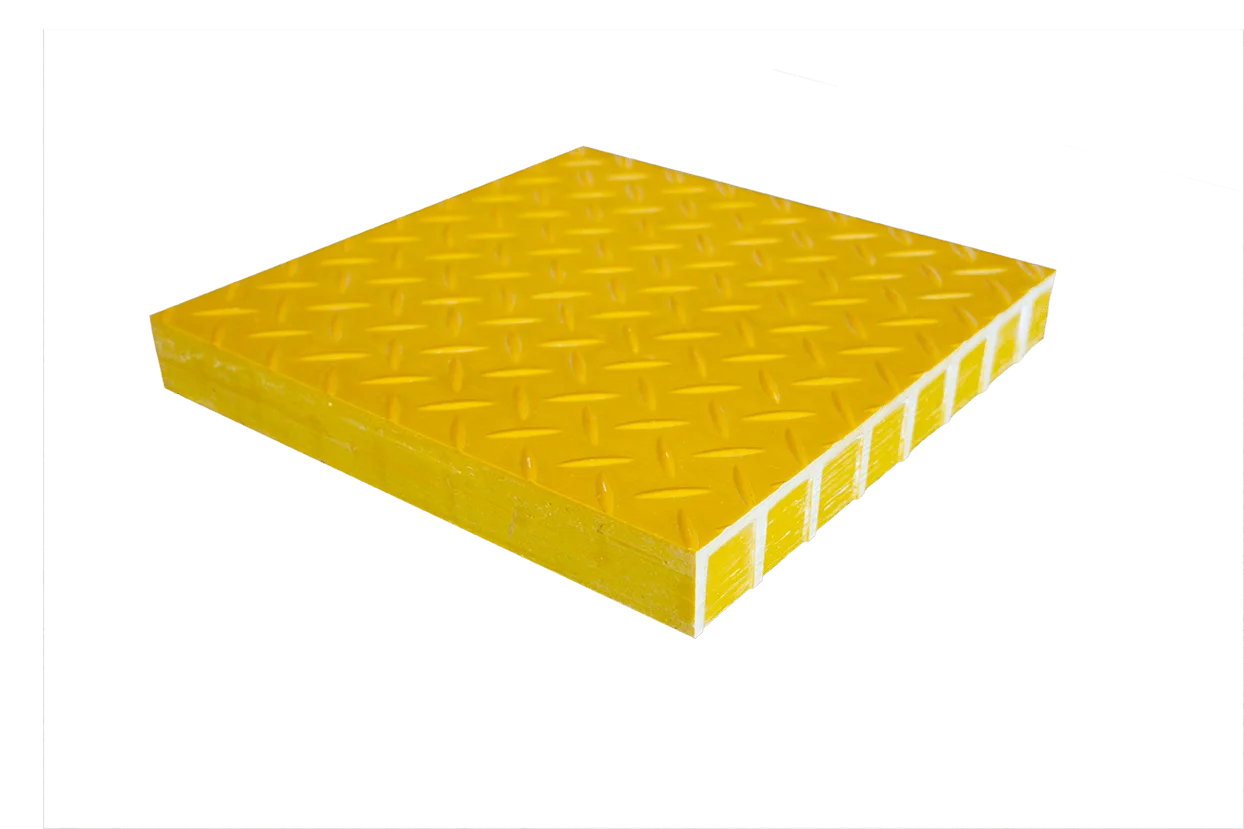

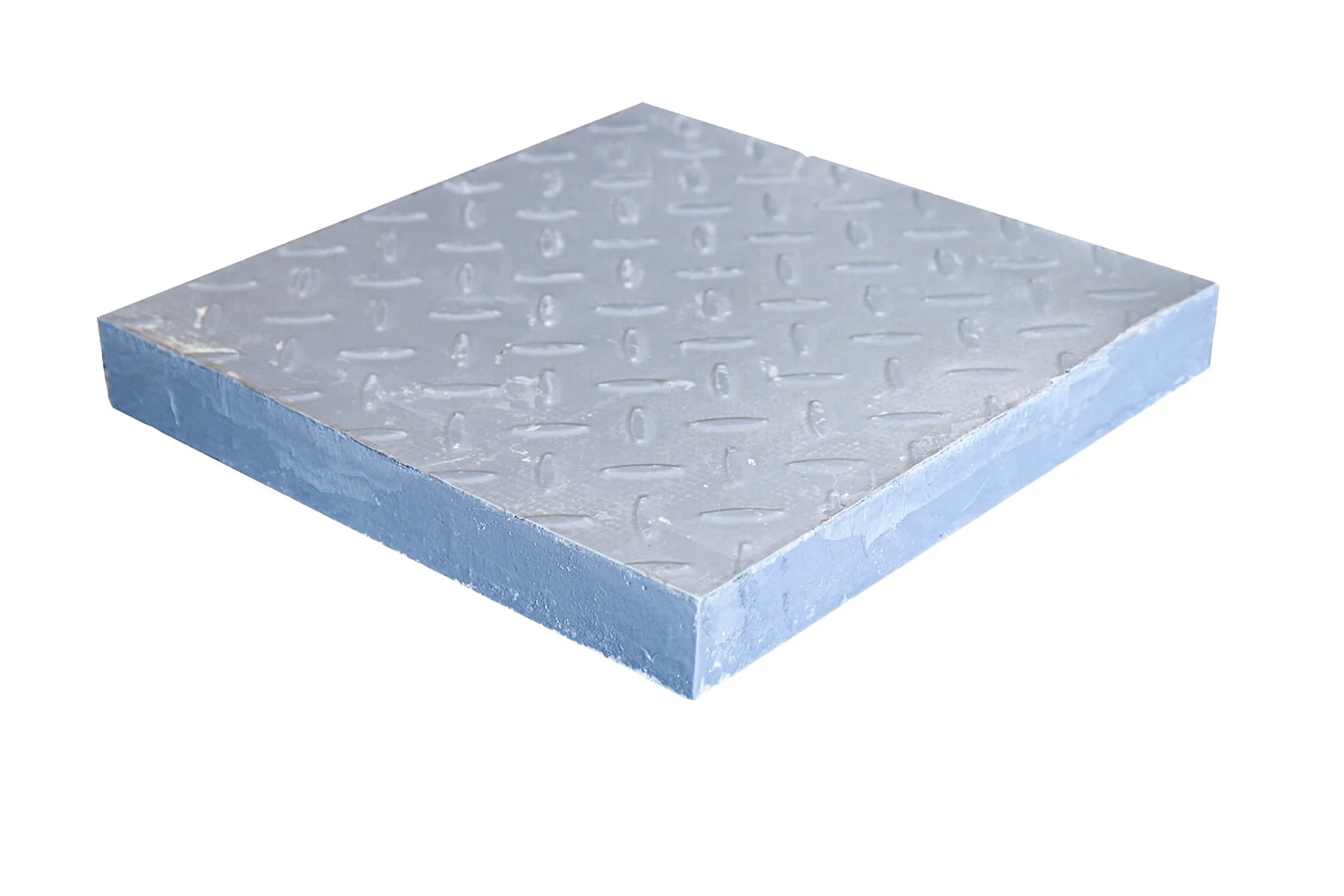

Dense fiberglass grating covers are used in facilities where a combined grating and plate construction is desired that is both corrosion resistant, easy to handle and easy to keep clean. The solution is based on cast gratings with a glued plate on one side and a tread/tear plate pattern that provides a non-slip surface.

Construction of dense grating decks

For tight grating decks, use article no. 15039 (grey colour) or 15040 (yellow colour) with standard plate size 1.22 × 3.66 m and height 38 mm. The plates are cut to size and placed next to each other during assembly with a gap between the plates of 3–5 mm. The gap is sealed tightly with elastic sealant, for example Sikaflex.

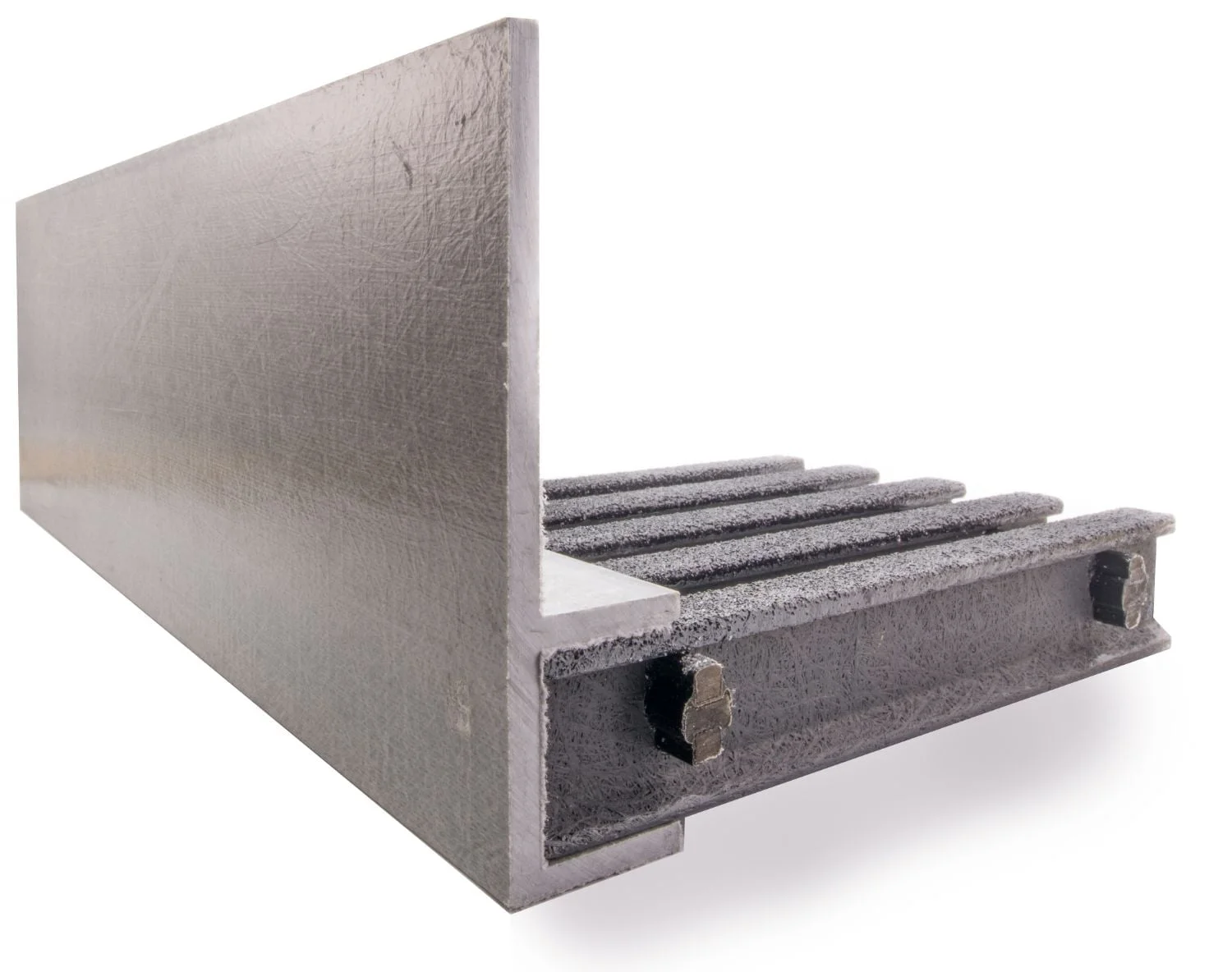

Around the outer edges of the grating deck, an upstand of typically 100 mm is established to prevent water from flowing out of the grating deck. For the upstand towards the wall and the skirting board at the railing, an angle profile in fiberglass is used, which is bolted down to the grating deck. Transitions are sealed with elastic sealant. An alternative is to use an F-profile (article no. 11431) in fiberglass around the grating deck.

Adaptation to arches and irregular geometries

In projects with curved platforms or round pools / tubs, the grating deck is cut to meet the curvature. To follow the curvature, a 3 mm fiberglass plate with a typical height of 140 mm is used, which is mounted to the cut surface of the grating deck and grouted tightly. The plate is supported at the bottom of the remaining deck with corresponding 3 mm fiberglass plate pre-adjusted in arc segments using CNC machining.

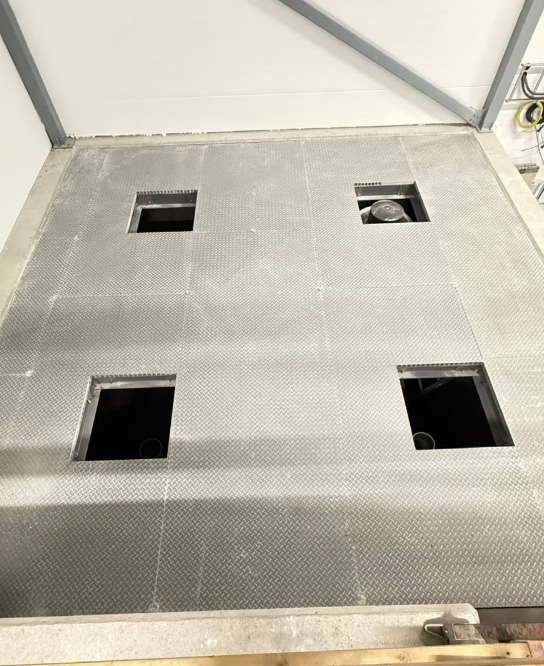

Drainage and penetrations

Grate covers can be installed with a slope for drainage. Standard plastic drainage pots can be installed on the underside to collect spills and washing water.

Pipe penetrations or other technical penetrations in the grating are drilled or cut and grouted with elastic grout. Fiberglass is easy to process at the installation site with hand tools such as a circular saw, angle grinder, jigsaw or hole saw.

Applications in practice

Fiberglass grating covers are used where equipment and instruments located on the underside of a platform or mezzanine need to be protected from possible spills from the overhead deck. This can be liquids from operating operations, leaks or water from cleaning processes.

Typical applications are in water treatment plants, fish farming, the process industry and areas where there are requirements for washable surfaces and controlled collection of liquids.

Installation conditions

The installation itself is relatively simple, and fiberglass can be cut and drilled with ordinary tools without heat or sparks.

Closed grating decks take slightly longer to install than open gratings due to jointing and adjustment of sheets and profiles. Once decks are completed, they require little follow-up beyond visual inspection of joints and fasteners.

Fiberglass mesh covers are a practical solution for facilities that require tightness, corrosion resistance and easy cleaning. They are flexible and can be used for both straight and curved structures. The solution is particularly suitable where low maintenance and a predictable lifespan are desired.