FireP

REBAR

Fiberglass rebar has a number of advantages and is a current alternative for reinforcing several structures.

SGP REBAR is GRP reinforcement for internal reinforcement of concrete structures. The reinforcement system consists of non-metallic bars and other parts made of fiber reinforced polymer. Fiberglass reinforcement provides an environmentally friendly alternative that reduces both repair and maintenance costs. The reinforcement will perform optimally over a long period of time without corroding.

"Fiberglass reinforcement stands out in several ways. We know how to get the most optimal use of the reinforcement."

– Elling Stangeland, general manager

"Fiberglass reinforcement stands out in several ways. We know how to get the most optimal use of the reinforcement."

– Elling Stangeland, general manager

Benefits

Resistant

against corrosion

Fiberglass reinforcement can withstand highly corrosive environments. The material can be exposed to water, moisture, salt, gas, chemicals and other acidic or alkaline factors. Traditional materials such as steel will have problems, which further leads to expansion and damage to the concrete. In many cases, fiberglass reinforcement will provide better quality, longer durability and better performance over time.

Simple and safe

installation

The low weight of fiberglass makes it easy to handle, transport and install. The reinforcement bars have, among other things, a sealed surface that causes less irritation to the skin during work, and it protects the material at the same time. The material can also be cut on site. This provides good opportunities to make adjustments quickly and easily during installation.

Magnetic neutrality

with insulating

properties

Magnetic neutrality means that fiberglass reinforcement can be used in situations where a whole range of other materials cannot. This could be buildings where various appliances and equipment are exposed to magnetic influences. The material and its surface act as an almost perfect electrical insulator. The reinforcement also has lower thermal conductivity and higher insulation compared to steel and other materials.

High tensile-

strength

The fiberglass has an excellent ability to stretch and still maintain a high level of strength. This is explained by the high quality glass filaments combined with high-performance resin. This gives the reinforcement very high tensile strength and long durability.

Excellent binding

for concrete

The rods are designed for optimal cooperation between fiberglass and concrete. The reinforcement is manufactured with rigid wave shapes that provide excellent bonding effect to any concrete structure. The material properties ensure high load capacity.

Cost-effective

with low CO2 emissions

The fiberglass retains a high degree of strength despite its low weight. This means less strain on production, installation and transportation. This keeps costs down and reduces emissions of greenhouse gases such as carbon dioxide.

Unlike other types of reinforcement, fiberglass can be easily adjusted, cut and adapted directly on site, and it does not require any special tools. This great flexibility is why many people choose fiberglass reinforcement.

FireP

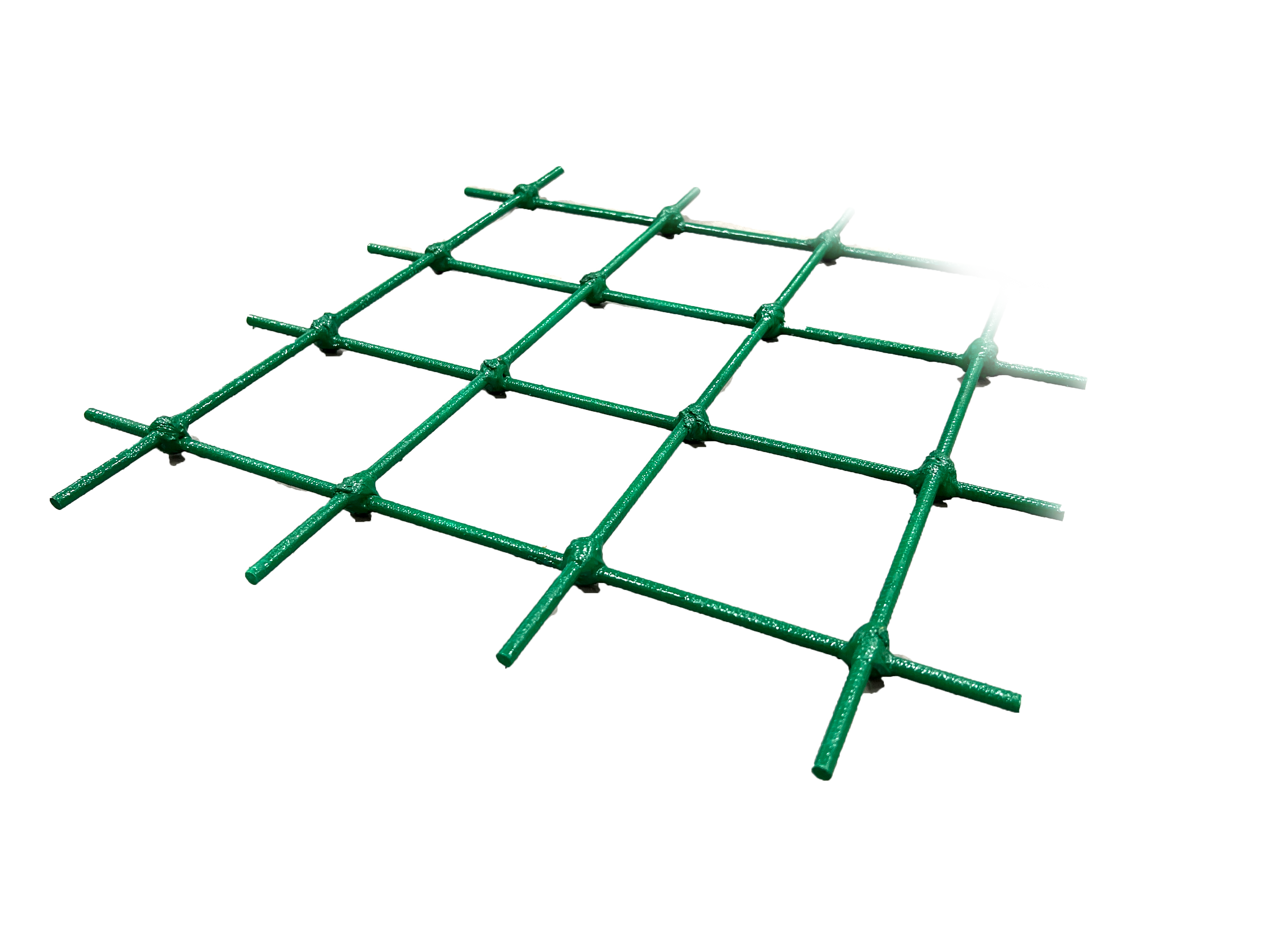

Powermesh

Strong, flexible and corrosion-free mesh for reinforcing concrete.

Powermesh is a strong fiberglass mesh for reinforcing concrete structures. The mesh is bound together by strong knots that can withstand heavy loads on a par with welded steel mesh. Powermesh has all the same advantages as FiReP Rebar.

Applications

The sum of all the advantages means that fiberglass reinforcement can be used for a wide range of applications.

- Temporary applications (Soft-Eyes)

- Membrane walls

- Drilled pile walls

- Railway plate reinforcement

- Concrete slabs using induction loops

- Facade panels

- Renovation and strengthening

- Infrastructure building

- Highways

- Tunnel segments

- Foundation

- Rockfall protection

- Renovation and strengthening

- Shotcrete reinforcement

- Pre-fabricated elements