Rust, maintenance and replacements. Challenges Ardyne AS has solved with the help of innovative fiberglass solutions.

Ardyne The company is a ohoil service company seam is specialized in delivering services and products to most oil companies on the Norwegian continental shelf within P&A (plug duck abandonm(ent) and recovery. Their Norwegian premises at Tananger consists of an office building and two large workshop halls. There is maintenance and repairs of existing equipment, while they have their own R&D department that works on developing new products.

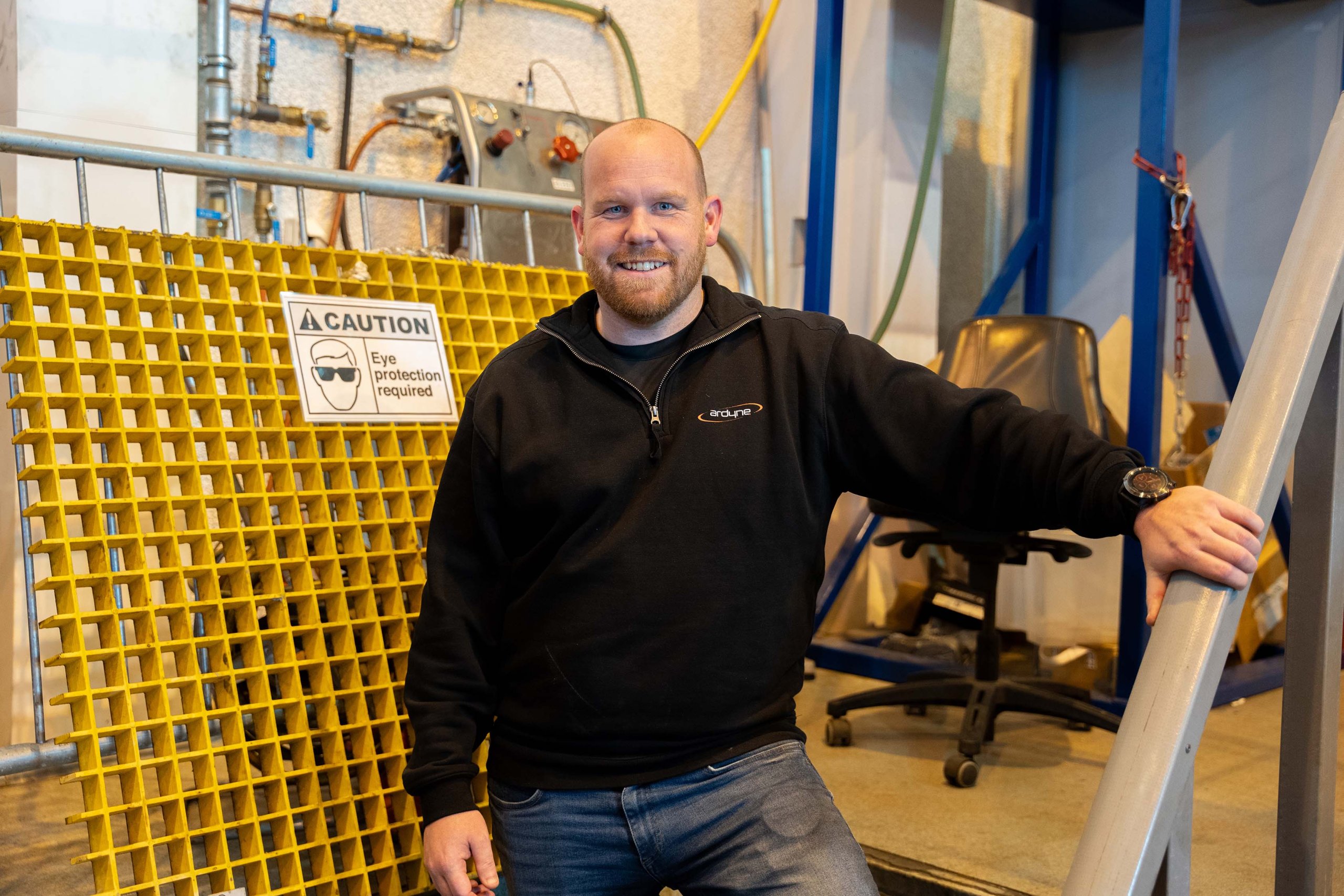

Just inside the workshop doors sits Kenneth Frøyland.

Kenneth is the Workshop Supervisor and works to plan and organize the work that takes place in the workshop, as well as ensuring that they have all the equipment they need to deliver what customers want.

Kenneth is committed to creating a safe and positive environment at work and tries to remove unnecessary friction, and has contacted us on several occasions to solve these very challenges.

– We have come up with ideas and you have delivered solutions.

That's what Kenneth Frøyland said about the collaboration between Ardyne AS and Glassfiber Produkter AS when we visited their premises in mid-October.

It started with a test chamber

It all started when Ardyne was building a test chamber to pressure and function test their equipment. To do this in the safest way possible, the tests are carried out in the test chamber. There they remove air, add liquid and check that it is sealed by exposing it to 5000 psi of pressure.

Previously this was open, but now the entire chamber is covered with yellow grilles that can be opened and closed as needed. We have also supplied and installed a staircase for easy access to the test chamber.

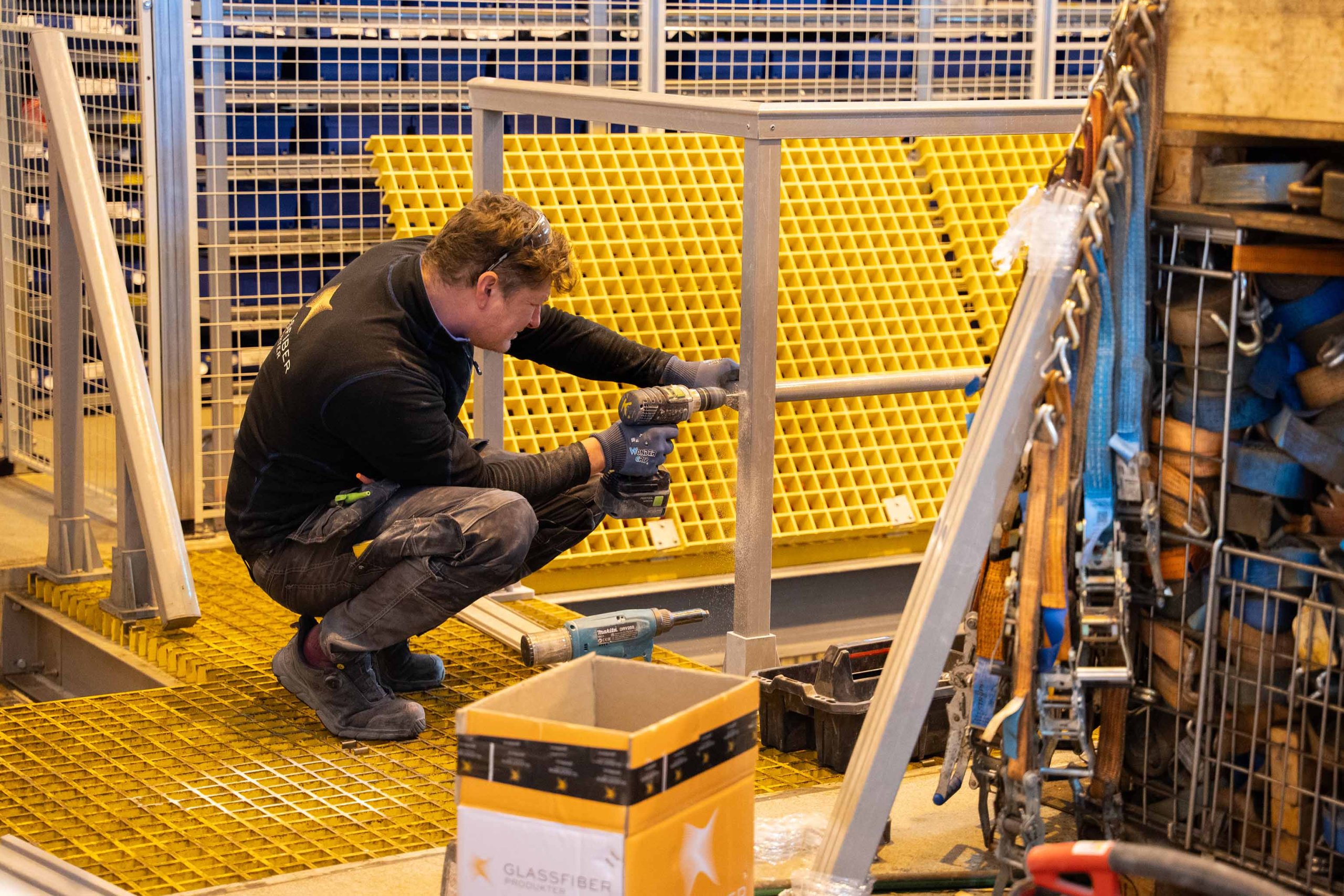

Our last job for Ardyne was a modification of the test chamber.

We have now installed railings around the test chamber opening so that it is safe to leave it open.

Installation of railings for the test chamber.

Kenneth in front of the open test chamber.

A resistant material for a corrosive environment

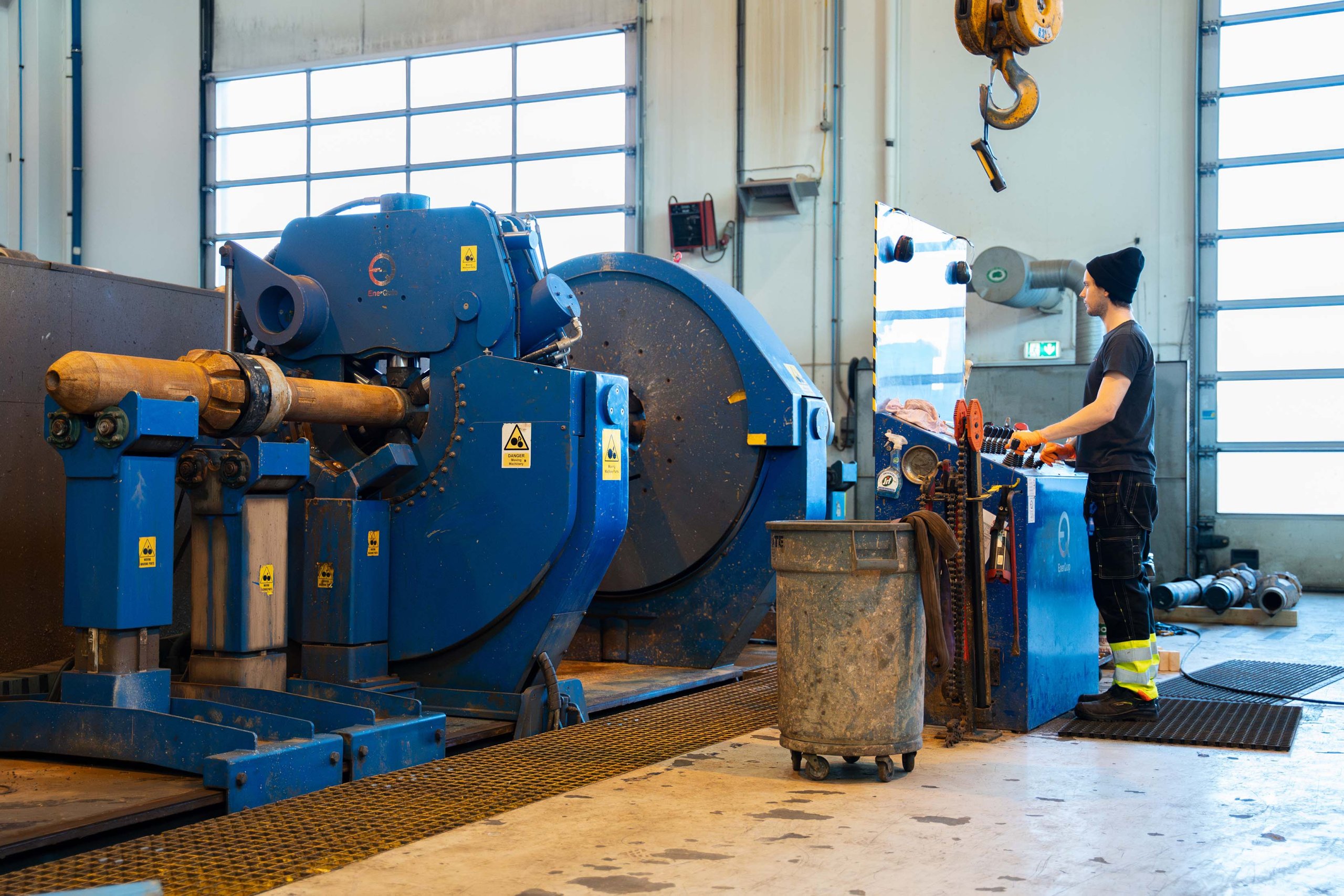

In the second hall is a breakout machine. Its task is to assemble and disassemble the equipment Ardyne is developing and working on.

To cope with the spillage that occurs, the area around the machine is equipped with fiberglass mesh grates. The specific design allows for efficient drainage of spillage, and the lightweight construction makes it easy to remove the grate for cleaning.

Espen Bekkeheim shows off one of the fiberglass grates

under the breakout machine.

Thanks to the non-corrosive properties of the grating, Ardyne does not have to worry about rust and maintenance of the gratings.

The fact that fiberglass is virtually maintenance-free is one of the big reasons why Kenneth has chosen products from us for tasks like this.

Breakout machine surrounded by fiberglass grating.

A real acid test for the fiberglass, literally

To protect and remove surface rust from various workshop equipment, Ardyne has developed a solution in the form of an acid bath. The equipment is placed in a cage that is lowered into the acid bath.

Previously, Ardyne used materials that had to be treated, maintained and regularly replaced, but when Kenneth looked for new solutions, he contacted Magnar Stangeland from Glassfiber Produkter AS.

– It's always nice to receive requests from Ardyne, who are so forward-thinking that they focus on fiberglass when starting new projects at the workshop, says Magnar about being contacted by Ardyne.

After a quick phone call, the idea quickly became a practical solution, and production of the fiberglass cage was initiated.

Espen Bekkheim lowers the fiberglass cage into water after it is finished in the acid bath.

Fiberglass solutions

Our partnership with Ardyne AS perfectly illustrates the flexibility of fiberglass. Different challenges are solved in creative ways, and everything is realized using fiberglass.

– We greatly appreciate Ardyne as a customer, an exceptionally nice company to work with. They come up with an idea that we realize using fiberglass, Magnar continues about the work with Ardyne.

Kenneth is clear that he will contact Glassfiber Produkter AS in the future to realize his new ideas.

We at Glassfiber Produkter AS look forward to future collaboration.