What are gratings?

Grilles are our most popular product group and we have a wide selection of grills for most needs.

Each type of grating has its own suitable applications and strengths based on its structure, composition and manufacturing method.

Before we dive into the different types of gratings we offer, it's good to understand what a grating actually is, and what they are used for.

Simply put, grating is a collective term we use for gratings made of fiberglass profiles, which together form a robust surface with regular patterns. The openings allow light, air and water to pass through easily, which is important for applications where good ventilation and drainage are required. Gratings are often used in industrial areas, on bridges and in staircases.

The gratings we sell are made of fiberglass and are most often used for walkways and platforms. The fiberglass material means that the gratings are light, yet strong. This makes them easy to work with and adapt on site. The gratings are basically corrosion resistant to external environments and is therefore particularly suitable for environments prone to corrosion.

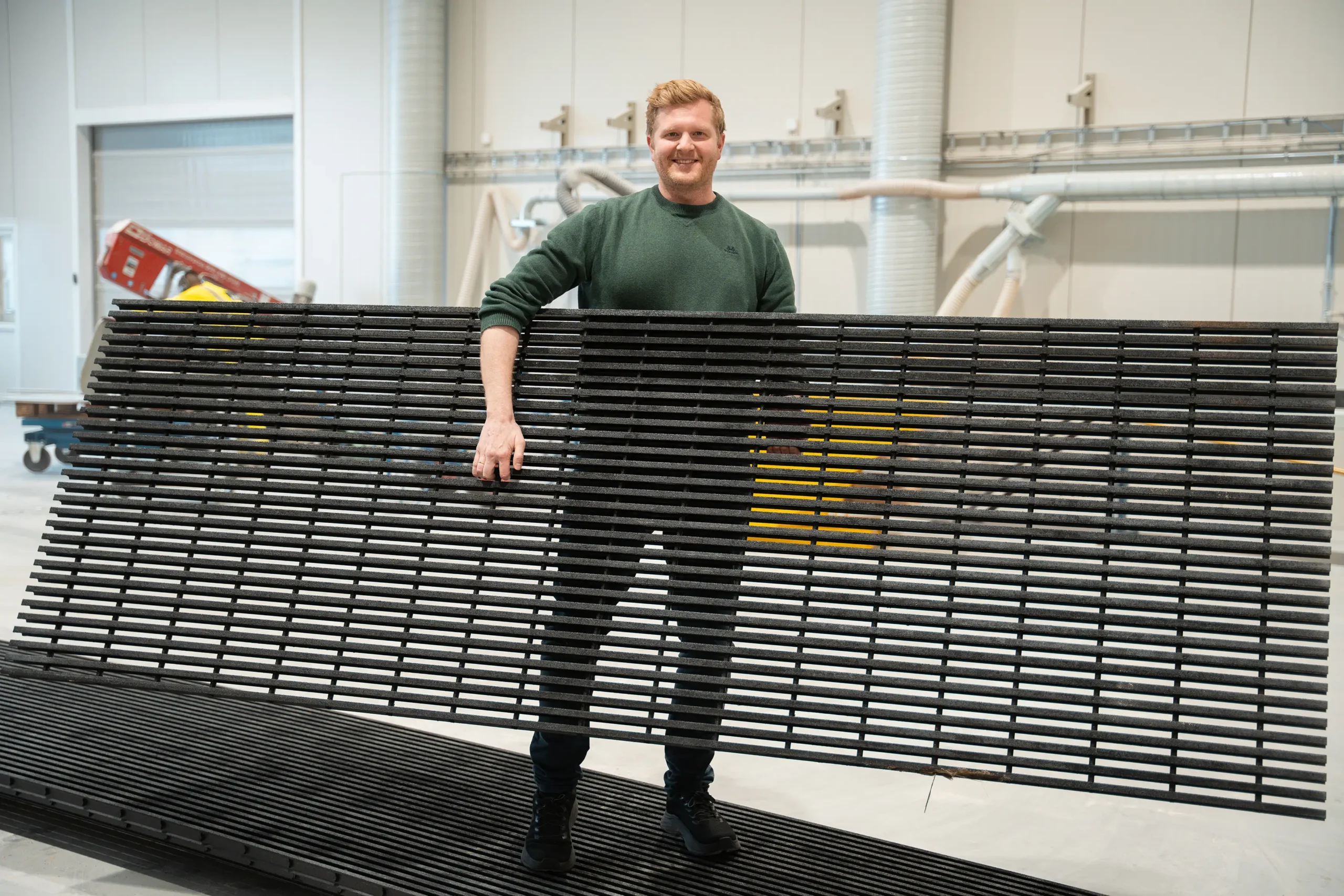

Magnar Stangeland shows samples of some of

our grilles.

Wire mesh gratings used as walkways on land-based fish farming facilities.

Gratings used as stair treads.

Our thinnest wire mesh used to make a cage used in acid baths.

The difference in the gratings

There are several ways we differentiate our gratings, based on how they are manufactured, what components they are made of and what applications they are intended for.

Production method

Let's look at the production method.

We stock goods produced using two different production methods:

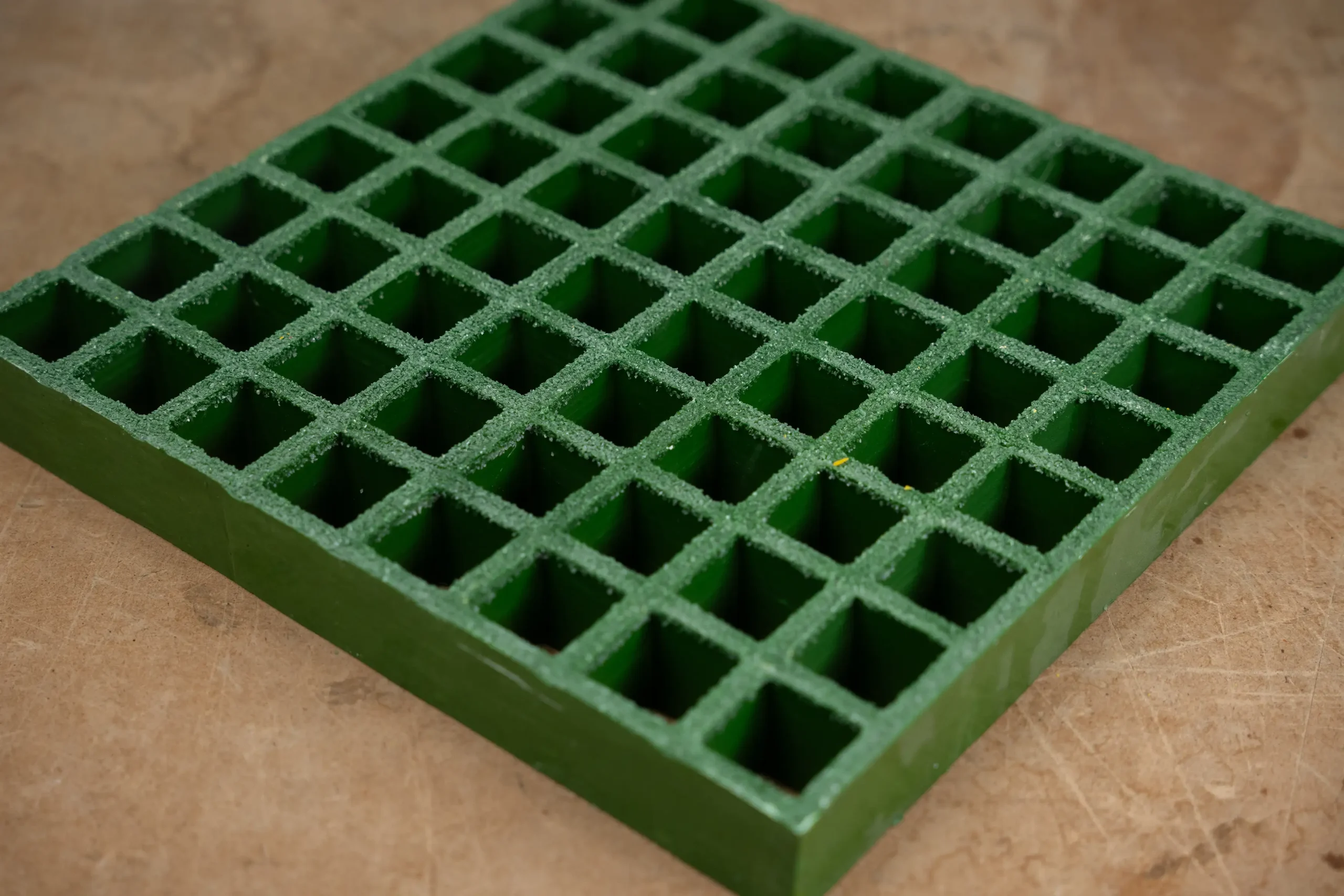

Molded grating

Cast gratings have a square or rectangular grid pattern. They are produced with a casting mold where bundles of fiberglass are laid in layers at a 90 degree angle. This provides a load-bearing capacity in both directions in the horizontal plane. Regardless of the way and manner in which the gratings are used, the strength will be distributed evenly across the grating.

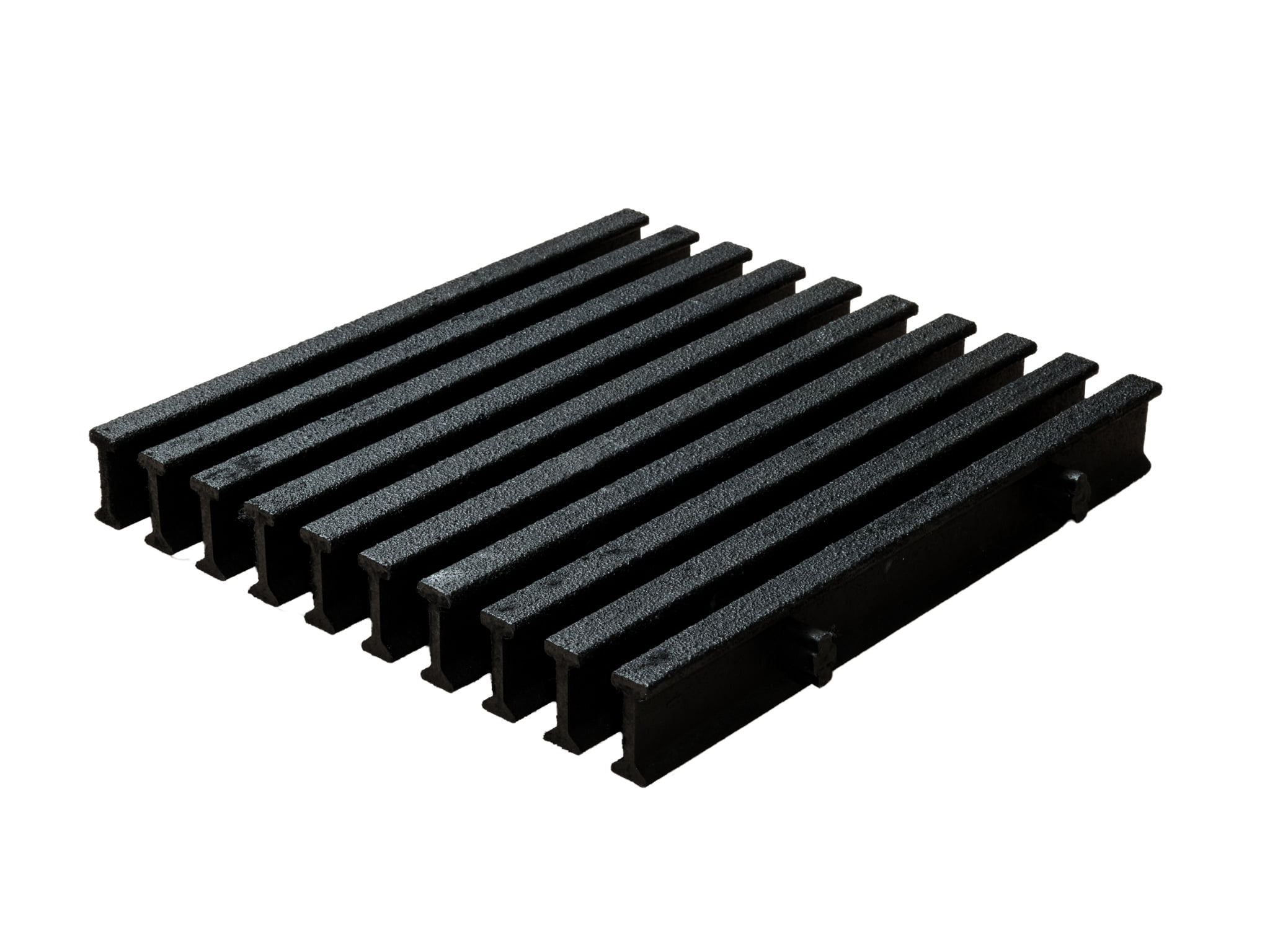

Profile-based gratings

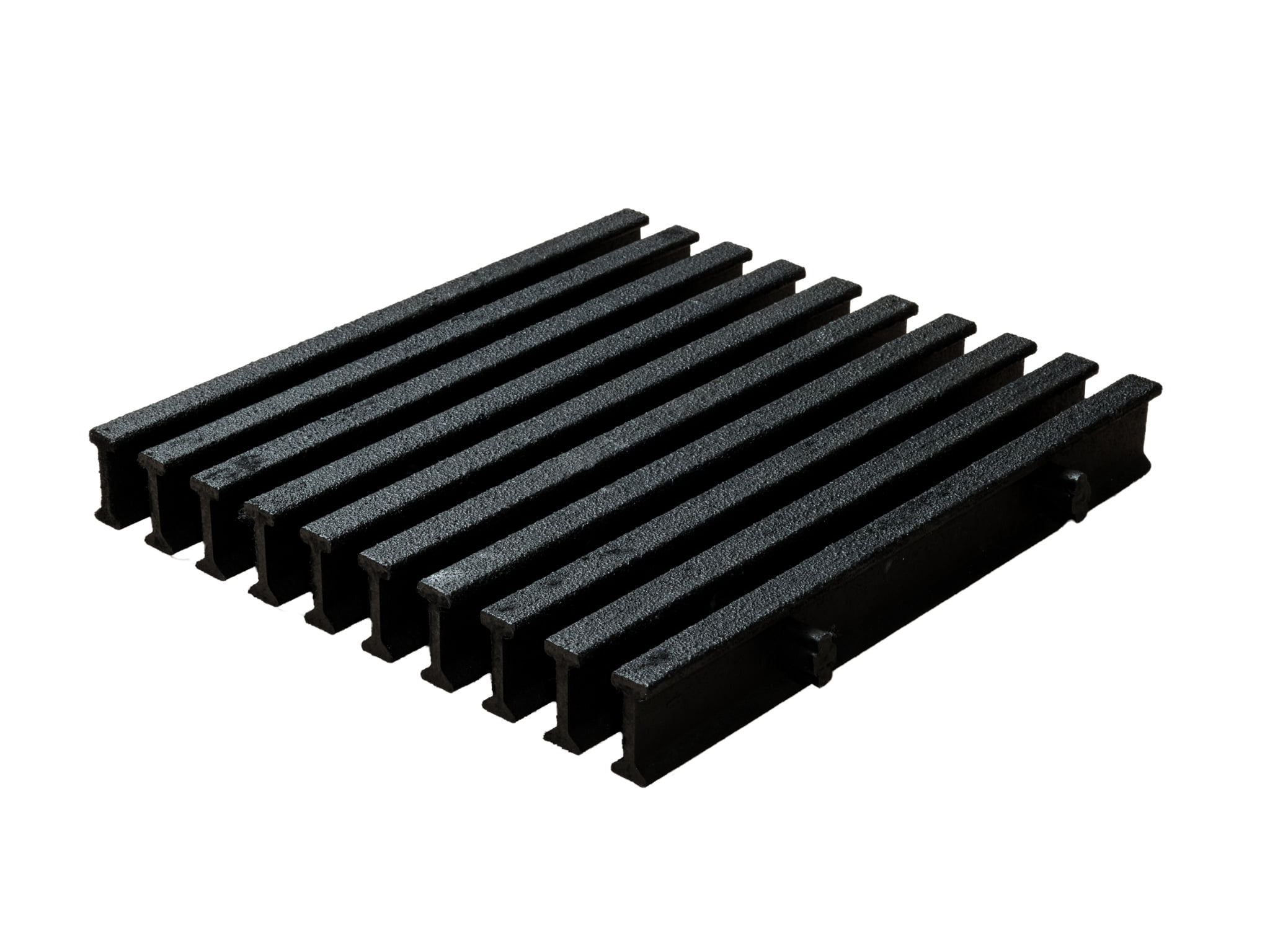

Profile-based gratings are assembled together from longitudinal I-profiles. The profiles are produced by pultrusion and assembled together with transverse profiles that lock the I-profiles in position. Unlike cast gratings, profile-based gratings have load-bearing capacity in only one direction.

Dimensions

The thickness of the grating and what we call profile thickness have a great impact on the strength of the grating.

Thickness of grate

We have grates with thicknesses from 12mm all the way up to 51mm.

This undoubtedly has a high effect on the strength of the grating. The thickness you choose should be based on the load to be carried and the possible free span.

Profile thickness

Another dimension of the grating that determines the structural strength of the grating is the profile thickness. By profile thickness we mean the thickness that makes up the pattern on the grating, whether it is cast or profile-based gratings.

Profile pattern and opening

Our cast gratings are designed with what we refer to as a profile pattern. This pattern is available in a number of different dimensions, and the combination of these dimensions and the profile thickness has a major impact on the strength and load-bearing capacity of the grating.

When we talk about openings, we are talking about our profile-based gratings. Opening refers to the distance between the I-shaped profiles in the grating, which is a key aspect of our profile-based gratings.

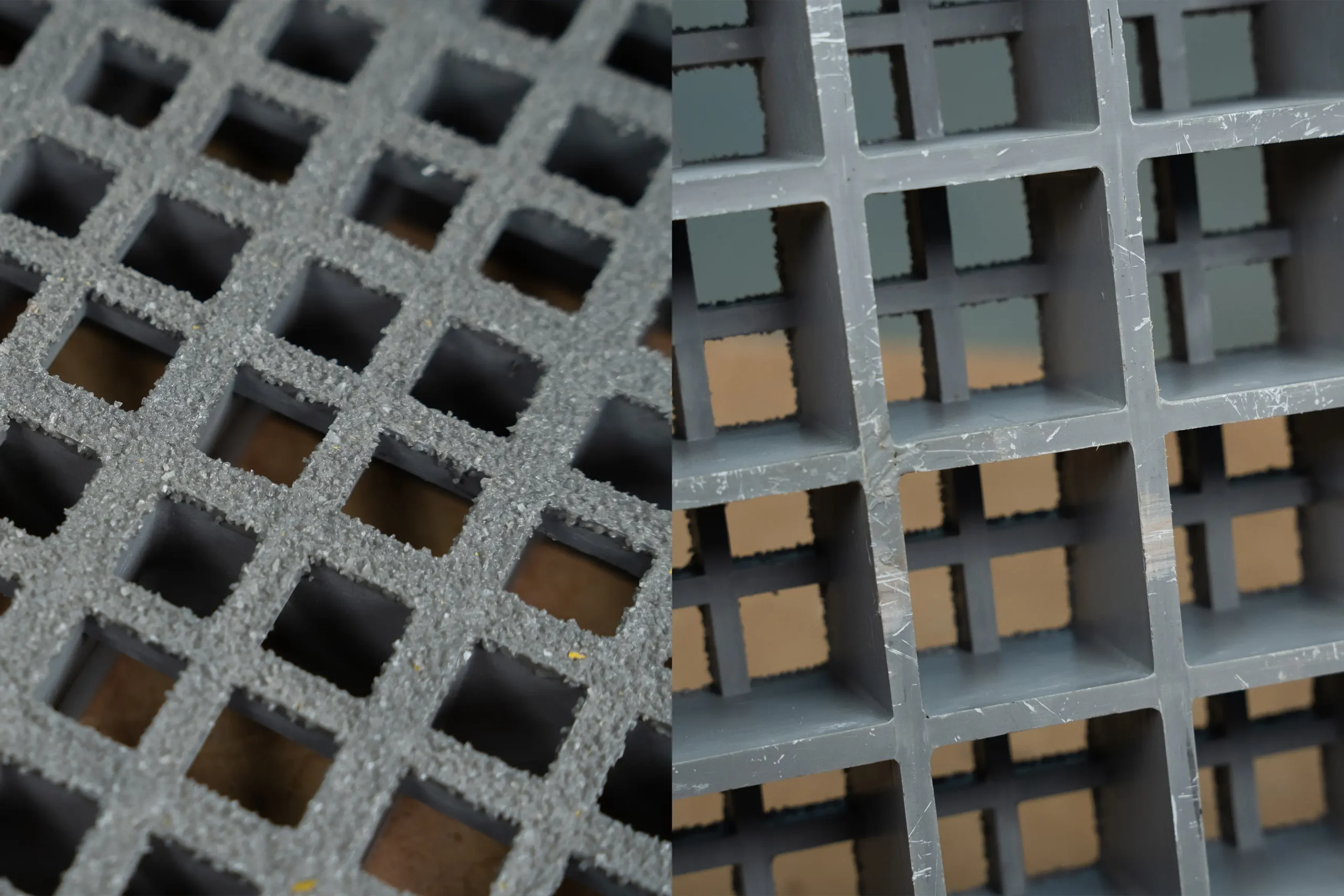

The difference in profile thickness.

Some of our grates have a different surface pattern than

main pattern.

Load

On the product pages for the gratings you will find a load table that shows the load the grating is designed for. This is a good tool if you are unsure.

on whether the given grating is strong enough for your needs.

Here is an example of a load calculation on one of our 38mm gratings:

It may look a little complicated, but we'll do our best to explain.

Open span

On the left side of the table you will see a list of open spans, i.e. the opening between underlying beams or supporting structure.

Load

The white numbers in the yellow field at the top are the load given in kN (kiloNewton). 1kN = 100kg.

When we say load, we are talking about the weight that the grating must withstand.

On the left side of the table we refer to two different types of load, ΔU and ΔC.

ΔU is the load evenly distributed per square meter, and ΔC is the concentrated load per meter or line load on 1 meter. This says something about how the load is applied to the grating. Δ stands for Delta and in physics means change. In this case, the change the grating makes when a load is applied.

Bending

The numbers in the middle of the table are how much the grating bends in mm. Take for example an open span of 800mm. Here we see that if we subject it to 8kN, it will bend 4.5mm with a uniformly distributed load (ΔU) and 8.8mm with a concentrated load per meter (ΔC).

Max and recommended load

On the far right of the table you can see the maximum recommended load and the breaking load. By recommended load we mean the load that Glassfiber Produkter AS, together with advice from the manufacturer, recommends. Breaking load is the load that the grating can withstand before it breaks in two.

Binder

As we have explained in this article about what fiberglass is and what it is made of, binder is one of the components of fiberglass.

We have gratings that consist of one of four different binders. All binders provide high strength, long life, and fire retardant properties; but some binders can also provide additional properties.

Orthopolyester

Orthopolyester offers a good balance between performance and cost, with sufficient chemical resistance for a variety of applications and good mechanical strength. This type is well suited for water treatment, architectural applications, and general industrial use.

Isopolyester

Isopolyester offers good chemical resistance and durability against weathering, making it a good choice for both outdoor and industrial applications where moderate exposure to chemicals occurs. The gratings using Isopolyester are cost-effective and offer solid strength.

Vinyl ester

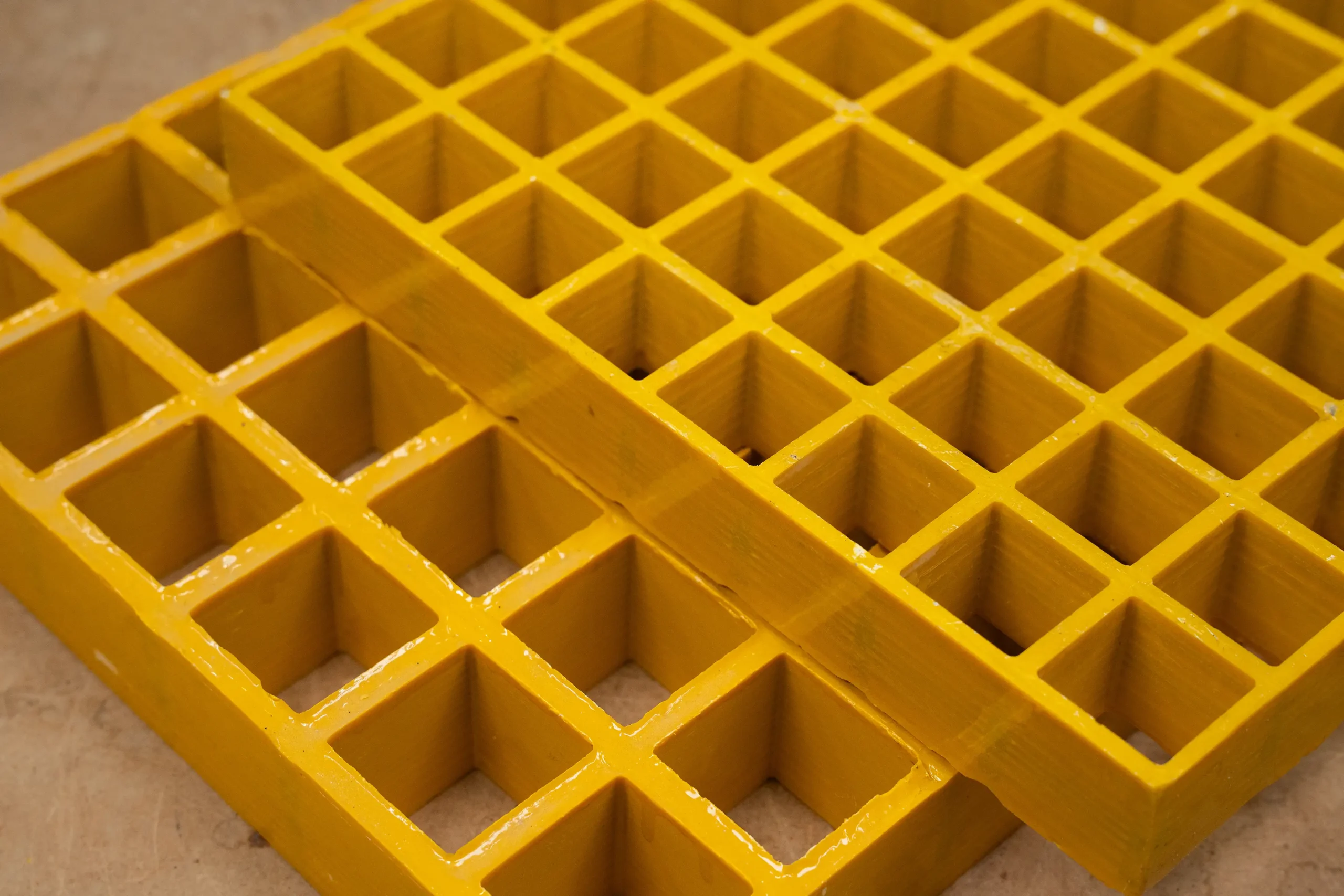

The vinyl ester binder is distinguished by its superior chemical resistance, especially against acids and strong alkaline chemicals. Vinyl ester is ideal for use in extremely corrosive environments found in the chemical industry. The gratings also have excellent mechanical properties and durability.

Phenol

Phenolic gratings are known for their exceptional fire resistance and low smoke emission, making them a preferred choice for fire-prone areas such as offshore and tunnels. They have good chemical resistance and contribute to increased safety.

Gratings with different types of binder, most often indicated by the color of the grating.

Surface

The surface of the gratings can also be available in different variants that are suitable for different uses.

Non-slip surface with finely divided sand

A surface with finely divided sand provides the highest friction and is our most slip-resistant surface. This is our standard surface and a good choice if you want high safety against slipping over a long period of time. Well suited for applications where deposits or fouling can occur.

Arc-shaped/concave surface

An arched surface occurs naturally during the casting process. This provides good slip resistance and, compared to a sand surface, is easier to keep clean.

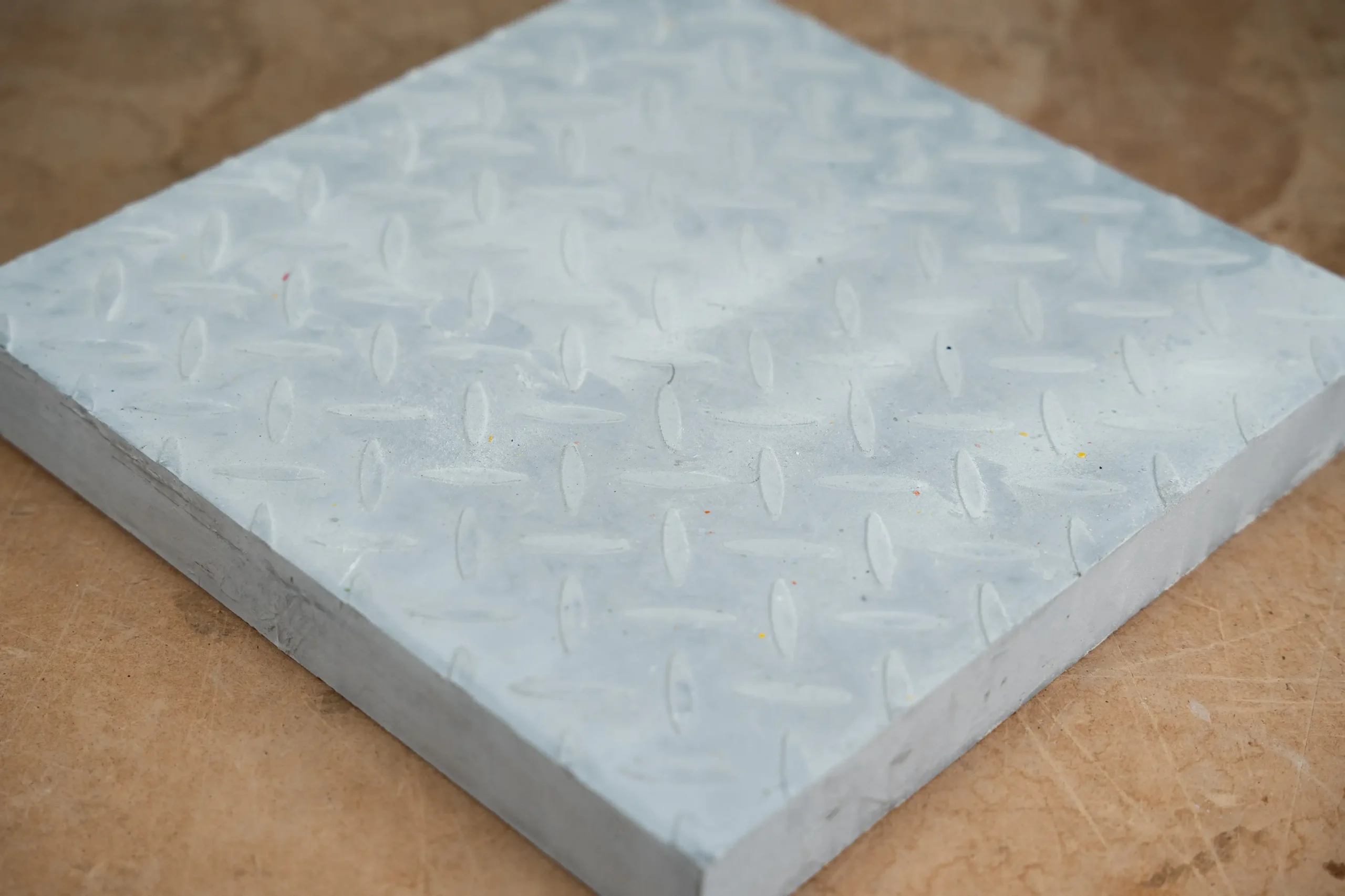

Grating with plate

Our gratings are available with a typical 3 mm plate covering the grid pattern. The grating then has a tight surface that can be used where, for example, water or other things need to be prevented from falling through the grating. The plate surface is supplied with finely divided sand as an anti-slip or with a teardrop plate pattern.

Smooth surface

Our final option is a smooth surface on both sides of the grating. This is only available for our 12mm thick gratings. Typically used for protection against moving machinery or rotating equipment.

Cast grating with a surface of finely divided sand.

Grating with a plate with a teardrop pattern.

Lattice categories

You now know the different components that go into creating our various gratings:

- Production method

- Dimensions

- Binder

- Surface

On our product pages, we divide our gratings into four different categories based on application and type of grating.

Cast lattice seats

Profile-based gratings

Heavy-duty gratings

Stair Treads

Molded grating

These are our cast gratings, which refer to the production method described earlier in the article. This category of gratings is our most versatile grating and is suitable for most applications. The gratings are available in thicknesses from 12mm all the way up to 51mm, and a profile thickness of 12mm.

Profile-based gratings

This type of grating often has a higher strength and is best suited for large open spans or other situations that require a higher degree of strength compared to cast gratings. This is due to the longitudinal I-profiles that provide high strength in one direction.

Heavy-duty gratings

If you need the toughest type of grating, then you are looking for heavy-duty gratings. These are available in both cast 51mm thick and profile-based 64mm thick. The profile-based version stands out with its profile pattern, which provides extra strength.

Stair Treads

Cast and profile-based stair treads are, as the name suggests, suitable for use as stair treads. The reason is their reinforced edge at the front, which is usually marked in yellow as a signal color. This is done to strengthen the points on the grate that experience the most stress, i.e. at the front.

Summary

Throughout this article, we have explored gratings – from basic explanations and applications, to the different manufacturing methods and components used. We have seen how dimensions and profile selection play a critical role in determining the strength of the grating and its suitability for specific applications. We hope you are now better equipped to consider which type of grating best meets your specific needs, whether for industrial walkways, platforms, stair treads, or other applications. By choosing the right product, you ensure long life, optimal functionality, and not least safety in your projects.

Anything else you're wondering about?

Do you have questions not answered in this article, or need advice and guidance?

Contact us!