Glassfiber Products carries a large assortment of different gratings. Among all the gratings we have, it can be a challenge to find the right type that meets your needs. Which grating you should choose depends on what, where and how it will be used. This article gives you an overview of what you should include in your assessment.

Molded and profile-based gratings

Molded grating have load-bearing capacity in both directions, making them strong and versatile, and they are suitable for most applications. No matter which way and how the gratings are used, the strength will be distributed evenly across the grating.

Profile-based gratings used in situations where there are large free spans or other factors that require a higher degree of strength. Unlike molded gratings, profile-based gratings have load-bearing capacity in only one direction. The profiles provide exceptional strength in one direction, which is very beneficial for certain applications.

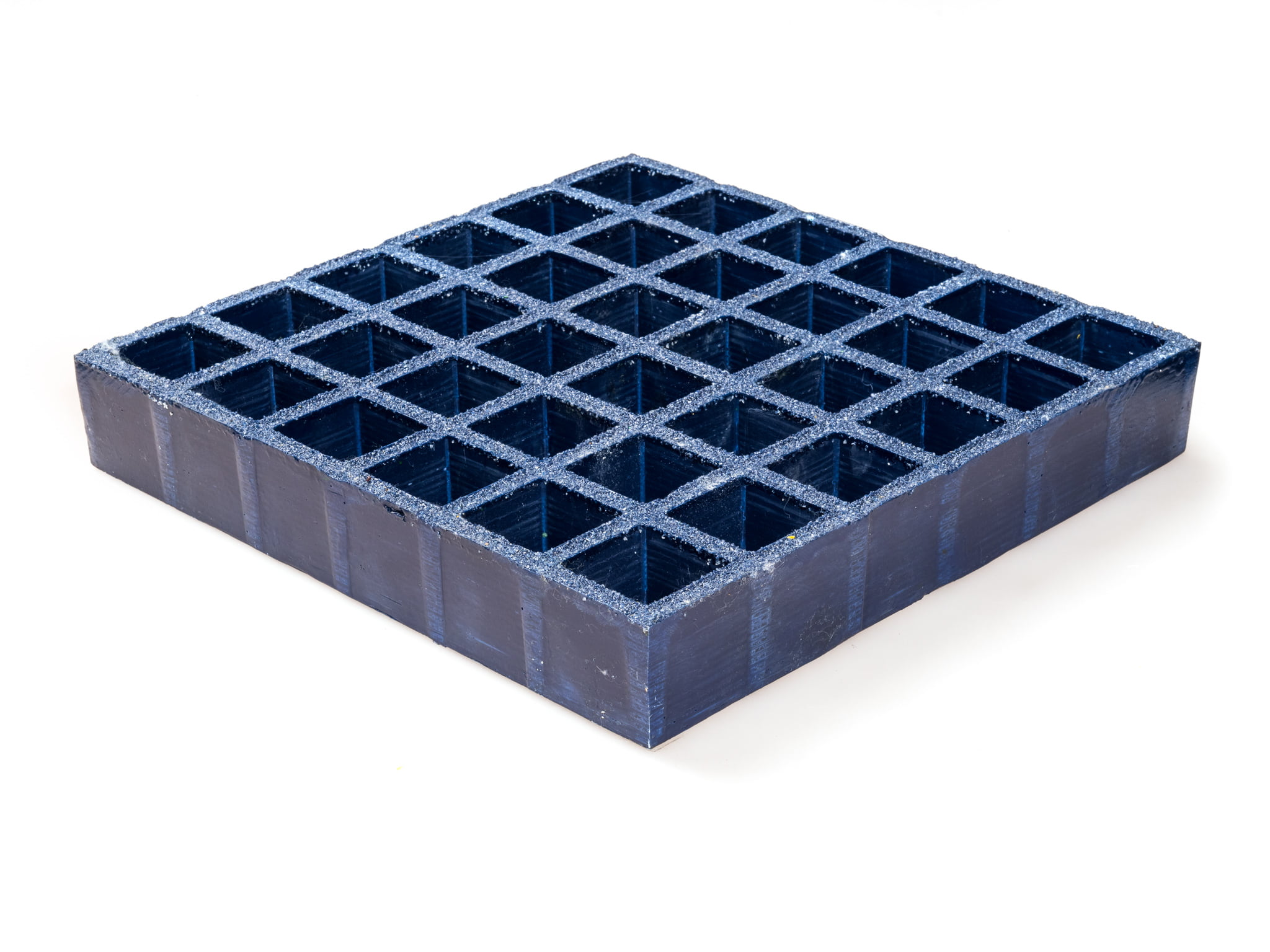

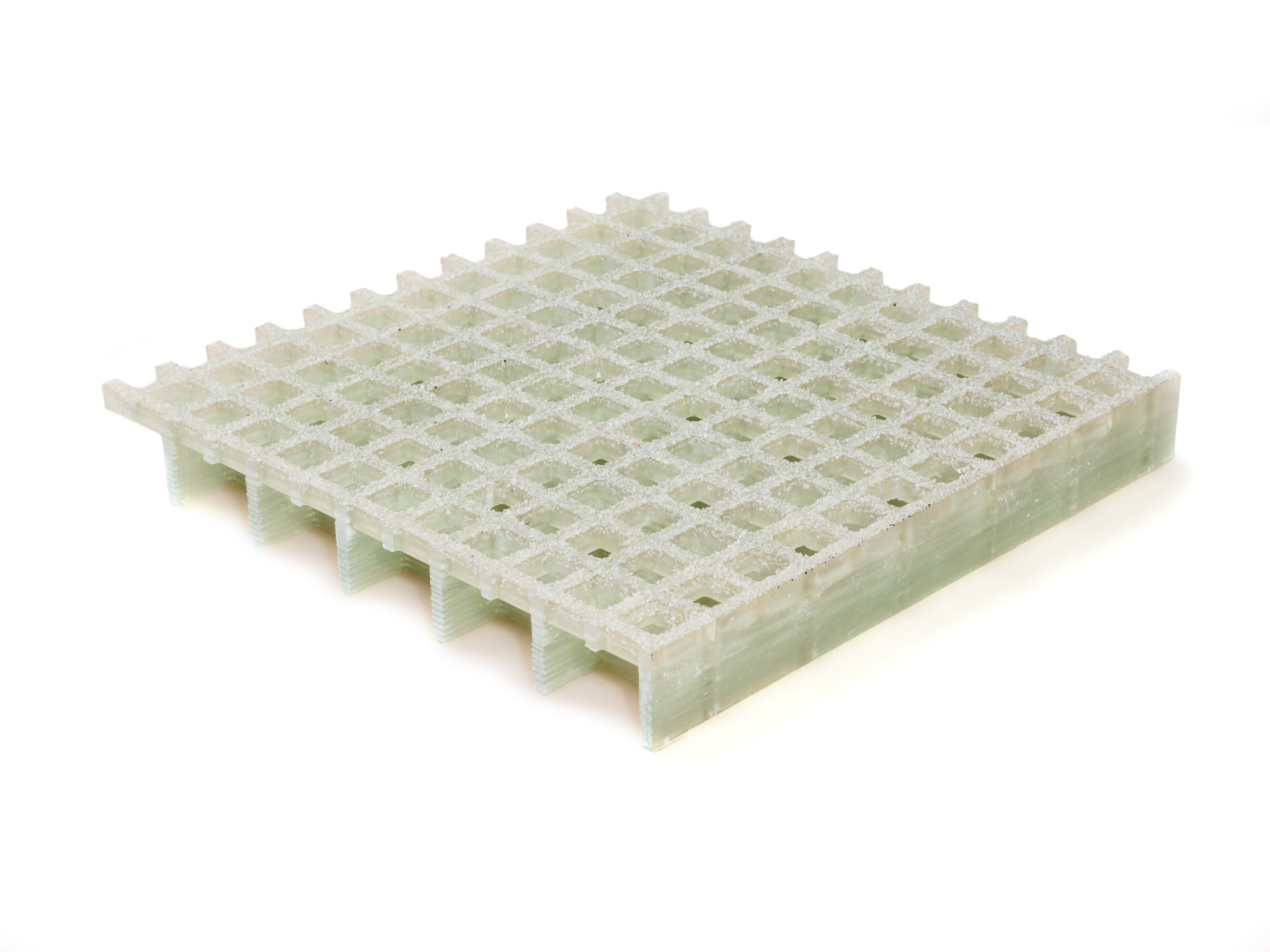

Molded grid with square pattern.

Grating mounted with I-profiles.

Sizes of the grates

The moulded gratings have a standard dimension of 3685 x 1219 mm, and the profile-based ones have a typical size of 6000 x 1000 mm. The gratings can be cut to size and combined exactly to suit the application.

Pattern and light aperture

The size of the openings in the gratings should be chosen based on the application. Our cast gratings have light openings from 11 x 11 mm to 42 x 42 mm. Openings of 38 x 38 mm are standard, unless other specific requirements are made. If, for example, there are bullet requirements, the gratings must have smaller openings. Smaller openings ensure that objects cannot fall through.

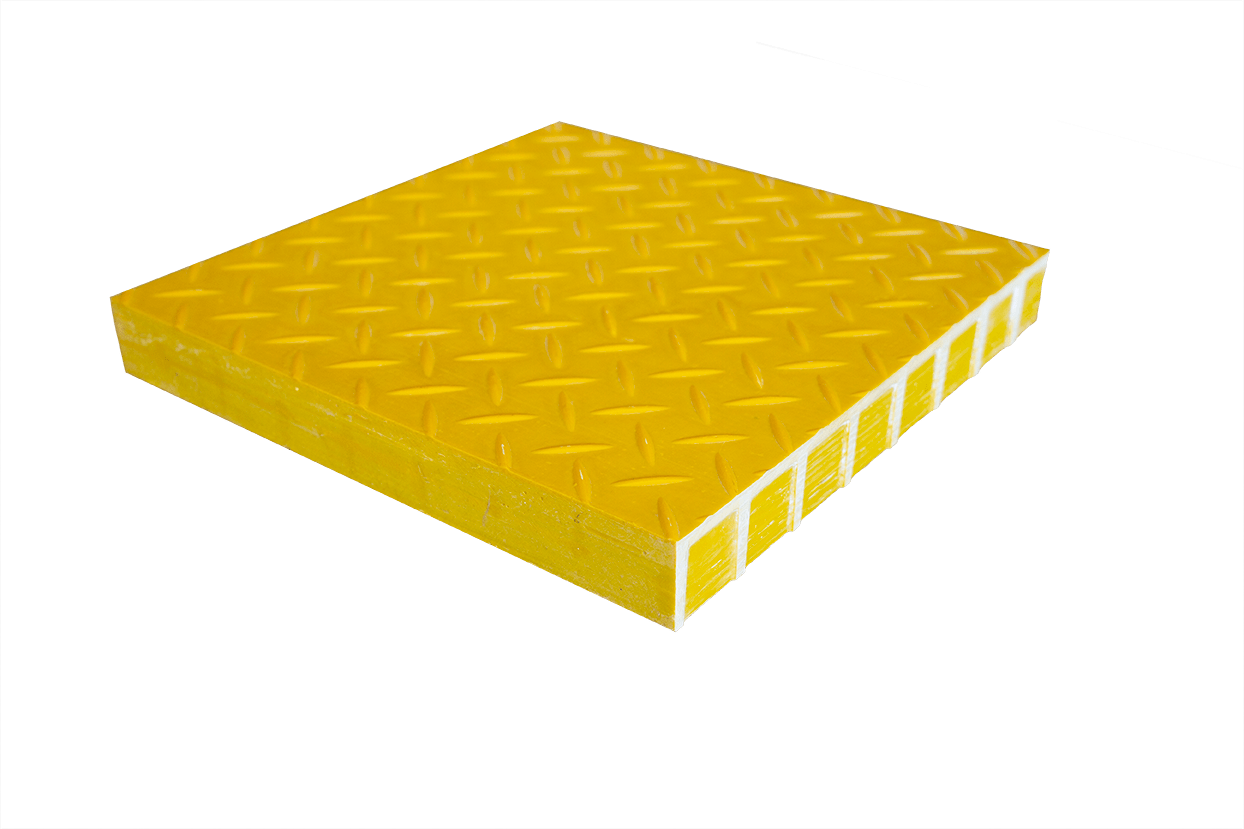

Full-coverage grates are also available. Some grates are manufactured with teardrop pattern which provides good footing.

Grate with small light opening 11 x 11 mm

Full-coverage grate with teardrop pattern

Non-slip surfaces

If slippery surfaces are a problem, you can resort to fiberglass gratings. Many of our gratings come with surfaces that reduce the risk of slipping. Gratings equipped with sand provide excellent slip resistance. Gratings without sand have concave surfaces that also provide a slip resistance effect, and are easier to clean.

Thicknesses and load

Our gratings are available in thicknesses from 12 mm to 51 mm. The thickness chosen should be based on the load it must withstand and the possible free span.

On each product page you will find load tables that show you the loads the gratings are suitable for. We help you Please help us find the right thickness and type of grate.

Gratings for stairs

Stair treads are whole sheets that can be cut to the desired size. The gratings are manufactured with a reinforced edge on each side so that it can be cut in the middle to better utilize the material.

The stair treads have nosings on each side.

We cut and customize

We have extensive experience in customizing gratings for a variety of applications. We cut, combine and customize the gratings to suit your needs. Fiberglass gratings are very versatile, and most things are possible with the right solutions.

Can be produced on request

It is entirely possible to produce gratings as neededThe gratings can be produced with desired RAL colors, designs and properties, adapted to the application. This provides great opportunity to tailor to what your project needs.

Some examples of special gratings we have delivered. You can decide everything from color, shape, surface, raw materials and other properties.